Hydraulic Lub tog raj kheej Seamless yeeb nkab

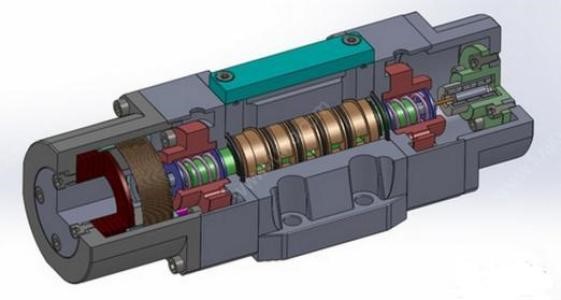

Hydraulic lub tog raj kheej seamless steel yeeb nkab yog tsim rau roj, hydraulic lub tog raj kheej, mechanical processing, tuab phab ntsa pipeline, tshuaj kev lag luam, hluav taws xob, boiler kev lag luam, kub kub, tsis tshua muaj kub thiab corrosion kuj seamless steel yeeb nkab, thiab nws yog haum rau roj av, aviation, smelting, zaub mov, kev txuag dej, hluav taws xob, kev lag luam tshuaj, tshuaj fiber ntau, kev kho mob machinery thiab lwm yam lag luam.

Vim yog qhov seem residual compressive kev ntxhov siab sab laug nyob rau hauv txheej txheej ntawm hydraulic lub tog raj kheej, nws yog qhov pab tau los kaw qhov micro tawg thiab cuam tshuam qhov nthuav dav ntawm yaig.Yog li, qhov kev tiv thaiv corrosion ntawm qhov saum npoo tuaj yeem txhim kho, thiab kev tsim lossis nthuav tawm ntawm kev qaug zog tawg tuaj yeem raug ncua, yog li lub zog qaug zog ntawm quilted raj tuaj yeem txhim kho.Los ntawm kev sib sau ua ke, txheej txheej ntawm kev ua haujlwm txias txias yog tsim rau ntawm qhov chaw dov, uas txo cov elasticity ntawm kev sib cuag nto ntawm kev sib tsoo khub.

Yog li ntawd, qhov hnav tsis kam ntawm cov phab ntsa sab hauv ntawm lub raj quilting yog txhim kho thiab qhov kub hnyiab los ntawm kev sib tsoo yog zam.Tom qab dov, qhov txo qis ntawm qhov roughness tuaj yeem txhim kho cov khoom sib xws.

Rolling yog ib hom chip dawb machining, uas siv cov yas deformation ntawm cov hlau nyob rau hauv chav tsev kub kom flatten lub micro unevenness ntawm workpiece nto, thiaj li hloov cov qauv nto, mechanical zog, zoo thiab loj.Yog li ntawd, txoj kev no tuaj yeem ua tiav ob qho tib si tiav thiab ntxiv dag zog rau tib lub sijhawm, uas yog tsis yooj yim rau kev sib tsoo.

Txawm hais tias siv txoj kev ua li cas, yuav tsum muaj cov cuab yeej tsis sib xws ntawm qhov chaw ntawm qhov chaw, ua rau staggered peaks thiab hav,

Rolling processing txoj cai: nws yog ib hom kev ua tiav siab, uas siv cov yam ntxwv ntawm cov yas txias ntawm cov hlau ntawm chav tsev kub, thiab siv qee qhov siab rau saum npoo ntawm lub workpiece los ntawm dov cov cuab yeej los ua cov hlau rau ntawm qhov chaw ntawm lub workpiece tsim cov yas ntws. thiab sau nyob rau hauv thawj residual qis concave trough, thiaj li yuav txo tau qhov roughness ntawm lub workpiece.Vim tias cov yas deformation ntawm cov hlau nteg ntho hlau, txheej txheem saum npoo hlau txias thiab cov nplej ua tau zoo, sib sau ua cov txheej txheem kev ntxhov siab ntau dua.Lub hardness thiab lub zog ntawm qhov saum npoo yog txhim kho, yog li kev hnav tsis kam, corrosion kuj thiab compatibility ntawm workpiece nto yog txhim kho.Rolling yog ib txoj kev txiav dawb yas ua.

Qhov zoo ntawm seamless steel yeeb nkab rau hydraulic lub tog raj kheej:

1. Cov nplaim roughness tuaj yeem ncav cuag RA ≤ 0.08 & micro;M.

2. Lub ovality yuav ≤ 0.01mm.

3. Lub hardness saum npoo yog nce ntxiv kom tshem tawm cov kev ntxhov siab deformation, thiab hardness yog nce HV ≥ 4 °

4. Tom qab machining, muaj cov seem kev ntxhov siab, thiab lub zog qaug zog yog nce los ntawm 30%.

5. Nws tuaj yeem txhim kho qhov zoo sib xws, txo qhov hnav thiab ua kom lub neej ntev ntawm cov khoom, tab sis cov nqi ua haujlwm ntawm cov khoom raug txo.

Txhim kho qhov qaug zoggth ntawm lub cev quilted.

Txhim kho qhov hnav tsis kam ntawm sab hauv phab ntsa ntawm cov yeeb nkab quilted.

1. Cov nplaim roughness tuaj yeem ncav cuag RA ≤ 0.08 & micro;M.

2. Lub ovality yuav ≤ 0.01mm.

3. Lub hardness saum npoo yog nce ntxiv kom tshem tawm cov kev ntxhov siab deformation, thiab hardness yog nce HV ≥ 4 °

4. Tom qab machining, muaj cov seem kev ntxhov siab, thiab lub zog qaug zog yog nce los ntawm 30%.

5. Nws tuaj yeem txhim kho qhov zoo sib xws, txo qhov hnav thiab ua kom lub neej ntev ntawm cov khoom, tab sis cov nqi ua haujlwm ntawm cov khoom raug txo.

Siv rau cov kua dej, boilers, siab siab seamless kav rau boilers, siab siab rau cov khoom siv chiv, geological drilling, roj drilling, roj tawg, roj laum dab tshos, tsheb qag, nkoj.

Piv nrog rau cov neeg kho tshuab kis tau tus mob thiab hluav taws xob kis tau tus mob, hydraulic kis tau tus mob muaj cov nram qab no zoo:

1. Ntau yam ntawm hydraulic kis tau tus mob tuaj yeem yooj yim thiab hloov tau raws li qhov xav tau.

2. Lub teeb yuag, me me, me me zog inertia thiab ceev cov tshuaj tiv thaiv ceev.

3. Kev ua haujlwm yooj yim thiab kev tswj hwm, uas tuaj yeem paub txog kev tswj hwm kev nrawm nrawm hauv ntau yam (kev tswj hwm nrawm mus txog 2000: 1).

4. Kev tiv thaiv overload tuaj yeem paub tau.

5. Feem ntau, cov roj ntxhia yog siv los ua qhov nruab nrab ua haujlwm, tus txheeb ze txav saum npoo tuaj yeem lubricated los ntawm nws tus kheej, thiab kev pabcuam lub neej ntev;

6. Nws yog ib qho yooj yim kom paub cov lus tsa suab /

7. Nws yog ib qho yooj yim kom paub qhov automation ntawm lub tshuab.Thaum lub electro-hydraulic ua ke tswj tau txais yuav, tsis tsuas yog ib tug ntau dua degree ntawm tsis siv neeg tswj txheej txheem yuav tsum tau paub, tab sis kuj tej thaj chaw deb tswj yuav tsum tau paub.